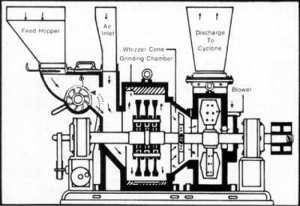

SINGHASINI Manufacturer of Impact Pulverisers are high speed, air swept, swing hammer type, multipurpose grinding mills capable of grinding soft to medium hard minerals & chemicals up to the hardness of 3.5 – 4.0 Moh’s such as Minerals, Bentonite, Clays, Limestone, Neeru, Dolomite, Coal, Bauxite, Barytes, Gypsum, China Clay, Soap Stone, Calcite, Pyrophillite, Mehandi, Spices etc. The main mill is equipped with a hopper below which is the STAR-FEEDER actuated by Pawl & Ratchet mechanism. The fine grinding is achieved by compression, shear, abrasion, attrition and impact of hammers / beaters on the materials against the replaceable serrated striking plates. The strong suction blower sucks the pulverized product and the air stream inside the mill carries the result product. In between the fan and the grinding chamber (having beaters / hammers) is the Whizzer Classifier consisting of blades with tips tapered to conform the contour of whizzer classifier cone. Counter current is set up at the periphery indicated by arrows; it rejects the coarse material back to the grinding chamber for re-grinding. Clamping the whizzer clamp at a suitable position can control fineness. The entire wearing parts consisting of grinding chamber, whizzer classifier and blower are lined with replaceable lining plates.

The function of the Cyclone Separator is to separate the fine pulverised materials from air which is re-circulated in the grinding chamber to complete the closed circuit grinding action. Inside the cyclone the dust laden gas enters a cylindrical chamber tangentially and leaves through a central opening. The air path forms a double vortex with the air spiraling downward at the outside and upward at the inside. The excess air coming in the system with feed material, etc. is bled off through a tubular type Dust Collector. The entire system works under suction except blower to cyclone pipe. The grinding chamber is provided with a small pocket where small pieces of iron, nuts and bolts are trapped.

There is a special type of Silica Separator (optional) attached inside the grinding chamber to remove free silica and other heavier impurities present in the raw material continuously from the grinding chamber. The main advantage of silica separator is, that it reduces the wear & tear inside the machine and also improves the quality of the product being grinded.The main driving shaft runs in two double row self aligning heavy duty Ball or Roller Bearings. An Automatic feeder is provided for regular and regulated feed.

STAR FEATURES:

- Lower Power Consumption.

- Fineness Control.

- Automatic Feeder.

- Low Operation & Maintenance Cost.

- High Grinding Efficiency.

- Whizzer Classifier.

- Open Circuit Grinding.

- Trap Iron Pocket.

- High Efficiency Cyclone Separator.

- Tubular Air Bag Filter.

- Continuous Silica separator.

- High Reduction Ratio.

- Heavy Duty Construction.

- Sixty Year of Experience.

PULVERISING CAPACITY (Kg/hr. Fineness of 100-325 Mesh)

| Material for Grinding | Size 20 | Size 25 | Size 32 Std. | Size 32 B.C. | Size 36 | Size 42 B.C. | Size 52 B.C. |

|---|---|---|---|---|---|---|---|

| Space Required (LengthXWidthXHeight) | 10 Ft X 5 Ft X 13 Ft | 13 Ft X 6 Ft X 16 Ft | 15 Ft X 7 Ft X 18 Ft | 15 Ft X 7 Ft X 18 Ft | 15 Ft X 8 Ft X 18 Ft | 22 Ft X 10 Ft X 22 Ft | 24 Ft X 12 Ft X 25 Ft |

| Alum | 175 | 350 | 500 | 700 | 900 | 1050 | 1550 |

| Battery Separator | 24 | 48 | 98 | 120 | 136 | 200 | 320 |

| Bauxite | 200 | 350 | 500 | 650 | 850 | 1000 | 1500 |

| Bentonite | 250 | 500 | 800 | 1500 | 1800 | 2250 | 3400 |

| Besan | 200 | 400 | 800 | 1000 | 1200 | 1500 | 2250 |

| Calcite | 250 | 400 | 550 | 800 | 1100 | 1300 | 1950 |

| Chalk | 200 | 400 | 700 | 1100 | 1500 | 1800 | 2700 |

| China Clay | 250 | 450 | 800 | 1000 | 1300 | 1600 | 2400 |

| Chromite | 100 | 150 | 250 | 350 | 450 | 550 | 825 |

| Coal | 250 | 400 | 600 | 900 | 1200 | 1500 | 2250 |

| Coconut Shell | 22 | 45 | 90 | 115 | 125 | 190 | 300 |

| Dolomite | 175 | 325 | 550 | 900 | 1100 | 1200 | 1800 |

| Fish Meal (Dry) | 150 | 300 | 500 | 600 | 750 | 1250 | 2000 |

| Gram Dal | 200 | 400 | 800 | 1000 | 1200 | 1500 | 2500 |

| Graphite | 150 | 300 | 600 | 900 | 1200 | 1500 | 2250 |

| Guar Gum | 60 | 150 | 250 | 300 | 360 | 450 | 675 |

| Gypsum | 200 | 400 | 700 | 1000 | 1300 | 1600 | 2400 |

| Henna Leaf | 200 | 300 | 500 | 600 | 850 | 1200 | 2000 |

| Herbs | 80 | 150 | 200 | 300 | 350 | 500 | 700 |

| Hydrated Lime | 250 | 450 | 700 | 1000 | 1200 | 1500 | 2250 |

| Iron Ore | 125 | 250 | 600 | 800 | 900 | 1500 | 2500 |

| Kattha | 80 | 200 | 400 | 500 | 600 | 750 | 1100 |

| Lime Stone | 200 | 450 | 700 | 1000 | 1200 | 1500 | 2250 |

| Manganese Ore | 150 | 300 | 550 | 650 | 750 | 1000 | 1500 |

| Magnesium Oxide | 100 | 200 | 360 | 550 | 600 | 900 | 1450 |

| Mehndi | 200 | 300 | 500 | 600 | 850 | 1200 | 2000 |

| Mica Chips | 60 | 125 | 200 | 300 | 360 | 450 | 700 |

| Ochres | 250 | 450 | 700 | 1000 | 1200 | 1500 | 2250 |

| Pyrophyllite | 200 | 400 | 700 | 1000 | 1200 | 1500 | 2250 |

| Red Oxide | 150 | 400 | 700 | 1000 | 1200 | 1800 | 2700 |

| Salt | 100 | 250 | 500 | 600 | 725 | 1000 | 1500 |

| Sandal Wood | 60 | 85 | 200 | 250 | 300 | 400 | 600 |

| Saw Dust | 35 | 60 | 100 | 120 | 140 | 180 | 270 |

| Soap Stone | 250 | 450 | 700 | 1000 | 1200 | 1500 | 2250 |

| Soya Bean (DOC) | 150 | 400 | 800 | 1000 | 1200 | 1500 | 2300 |

| Tamarind Seed | 40 | 100 | 150 | 225 | 275 | 400 | 600 |

| Turmeric | 150 | 300 | 500 | 700 | 900 | 1200 | 1800 |

| Power reqd. for Pulveriser H.P. | 10 to 15 | 20 to 30 | 50 to 60 | 60 to 75 | 75 to 85 | 100 to 125 | 150 to 200 |

| R.P.M. of Pulveriser | 2400 | 2250 | 2000 | 2000 | 1900 | 1800 | 1500 |